Everything About Stretch Wrapper Repair: Why Timely Upkeep Is Necessary for Your Service

Prompt repair and maintenance of stretch wrappers are vital for business efficiency. Overlooking these makers can result in various functional challenges, including item damages and increased expenses. Normal assessments can avoid minor concerns from intensifying right into significant failings. Comprehending the significance of upkeep is essential for ensuring constant covering top quality. Nevertheless, numerous companies forget this important facet. What are the particular indications that indicate a stretch wrapper needs interest?

The Importance of Stretch Wrapper Upkeep

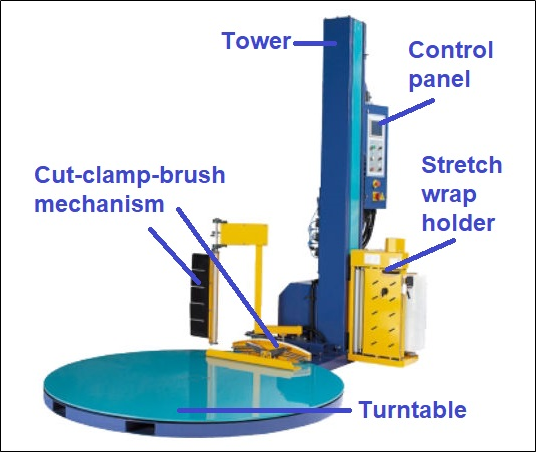

Keeping a stretch wrapper is vital for making certain excellent efficiency and longevity. Normal upkeep helps to avoid unanticipated break downs, which can bring about costly downtime and production delays. A well-maintained stretch wrapper operates effectively, guaranteeing that products are securely wrapped and prepared for transport.Routine examine parts such as the film carriage, roller setting up, and sensors are considerable; they assist recognize wear and tear before it escalates into considerable issues. Cleaning up the machine, lubing moving components, and adjusting stress setups can improve performance and prolong the tools's lifespan.Moreover, adherence to a maintenance schedule promotes a much safer working environment by minimizing the threat of accidents brought on by malfunctioning equipment. Investing time and sources in correct upkeep not only safeguards the stretch wrapper yet additionally contributes favorably to total functional effectiveness and cost-effectiveness. Ultimately, a proactive maintenance strategy is essential for maintaining productivity in any business counting on stretch wrapping innovation.

Typical Issues Came Across With Stretch Wrappers

Stretch wrappers can experience a range of usual concerns that affect their performance and integrity. One prevalent problem is inconsistent stress in the stretch film, which can lead to improperly protected loads. This inconsistency may originate from malfunctioning stress controls or damaged elements. Additionally, mechanical failings, such as malfunctioning motors or defective sensing units, can result in functional delays and raised downtime.Another usual problem is film breakage, commonly triggered by wrong stretch settings or substandard quality movie, which can interrupt the wrapping process. Misalignment of the tons can likewise occur, resulting in irregular wraps that concession stability. Buildup of particles or dust in the device can hinder its capability, calling for frequent cleaning and maintenance. Ultimately, electrical issues, like electrical wiring faults, might arise, potentially triggering system failings. Dealing with these typical concerns promptly is crucial for preserving excellent performance and lessening disruptions in packaging procedures.

Indications That Your Stretch Wrapper Demands Repair

Recognizing the signs that a stretch wrapper requires repair is necessary for preserving operational effectiveness. Unusual noise patterns, inconsistent movie stress, and constant movie breakage are key indicators that something might be amiss - stretch wrapper repair. Attending to these concerns without delay can stop much more considerable problems down the line

Unusual Sound Patterns

How can unusual sound patterns signify prospective problems with a stretch wrapper? These noises typically suggest underlying mechanical problems that call for prompt interest. For example, grinding or squealing noises might recommend worn bearings or misaligned components. Similarly, a sudden rise in quantity can indicate loose components or falling short electric motors, which can lead to operational failings. If a stretch wrapper produces uneven clattering or knocking noises, it may show that internal components are coming right into call with each various other inappropriately, threatening the equipment's performance. Disregarding these acoustic warnings can bring about more considerable damage and expensive fixings. For this reason, recognizing and resolving unusual noise patterns is necessary for maintaining the effectiveness and longevity of a stretch wrapper.

Inconsistent Film Tension

When movie tension is irregular, it usually signifies that a stretch wrapper requires repair work. This problem materializes as unevenly wrapped pallets, resulting in inadequate load security and boosted danger of item damage during transportation. Operators might observe that some areas of film are excessively tight while others are loosened, leading to ineffective containment. In addition, varying tension can cause the film to slide or move during application, compromising the total wrapping procedure. Such incongruities might come from mechanical troubles, such as worn rollers or malfunctioning tension controls. Addressing these issues without delay is vital to preserving operational performance and making certain that product stability is supported throughout the delivery procedure. Routine examinations can aid determine these problems before they intensify.

Frequent Movie Breakage

Regular movie breakage is a clear sign that a stretch wrapper may need repair work, more worsening problems related to inconsistent movie tension. This trouble not just interrupts the product packaging process yet can likewise lead to product damage and raised labor costs. When the movie continually breaks, it typically signals underlying mechanical issues, such as used rollers, inappropriate placement, or insufficient pre-stretch setups. Operators might discover that adjustments to stress setups are inefficient, showing a requirement for professional examination. Timely repair work can prevent production hold-ups and maintain product packaging honesty. Regular upkeep checks can assist recognize potential issues early, making certain peak performance and lowering the risk of regular film damage in future operations.

The Benefits of Routine Maintenance

Routine upkeep of stretch wrappers not only improves their performance but additionally expands their operational life-span. By routinely evaluating and servicing these machines, organizations can guarantee peak functionality and stay clear of unexpected malfunctions. Set up upkeep assists in determining possible concerns prior to they rise, reducing the threat of manufacturing delays.Moreover, properly maintained stretch wrappers offer regular covering top quality, which is crucial for shielding products during transport and storage space (stretch wrapper repair). This uniformity results in fewer product damages and enhanced customer satisfaction.Additionally, normal maintenance can boost energy effectiveness, causing reduced functional costs over time. It fosters a safer working setting by reducing the chances of accidents caused by malfunctioning tools. On the whole, aggressive upkeep methods add to a smoother workflow, allowing businesses to concentrate on their core procedures with confidence in their devices's dependability

Cost Implications of Neglecting Repairs

Ignoring fixings on stretch wrappers can lead to considerable economic consequences for businesses, as unaddressed concerns usually rise into a lot more extreme troubles. When operational inadequacies emerge, companies might experience boosted downtime, resulting in shed productivity and earnings. Additionally, constant failures can require emergency repair services, which are typically much more costly than routine maintenance.Moreover, the cost of damaged items because of inadequate wrapping can collect swiftly, resulting in greater waste and substitute costs. Inferior wrapping can likewise influence shipping effectiveness and enhance the threat of product returns, additionally stressing economic resources.In the long-term, continually ignoring fixings can reduce the life expectancy of tools, requiring expensive substitutes earlier than expected. Inevitably, the cumulative impact of these variables can webpage significantly impact a business's lower line, underscoring the importance of positive and timely maintenance strategies for stretch wrappers.

Best Practices for Stretch Wrapper Maintenance

Executing efficient maintenance practices for stretch wrappers can considerably boost their efficiency and long life. Regular evaluation is vital; drivers should inspect for wear and tear on components like belts, rollers, and movie dispensers. Cleaning the equipment regularly helps stop particles accumulation, which can lead to breakdowns. Lubrication of relocating components should abide by manufacturer guidelines to ensure smooth operation.Additionally, preserving appropriate stress and placement of the movie is important to achieve click for more the very best covering quality. Operators ought to also maintain detailed upkeep logs to track any type of problems and repair work, permitting prompt treatments. Training personnel on proper operation and upkeep treatments can decrease the risk of human error and lengthen equipment life. Ultimately, organizing routine professional evaluations can identify possible problems before they intensify, protecting consistent efficiency. By complying with these finest practices, organizations can lessen downtime and enhance the reliability of their stretch wrappers.

Selecting the Right Repair Solution for Your Stretch Wrapper

Choosing the best repair solution for a stretch wrapper is a necessary action in keeping functional effectiveness and lessening downtime. Businesses must focus on services that focus on stretch wrapper repairs, as these service technicians possess the needed know-how and experience to detect and solve problems effectively.It is advisable to examine possible repair services based upon their credibility, consumer testimonials, and response times. A reputable service must supply timely support and have a proven record of successful repair services. Additionally, organizations need to inquire concerning the schedule of replacement parts and whether the service utilizes OEM parts to ensure compatibility and longevity.Furthermore, recognizing the warranty and service agreements can give insight right into the degree of assistance used post-repair. By meticulously selecting a proficient fixing service, organizations can guarantee their stretch wrappers stay operational, therefore boosting productivity and maintaining a smooth workflow.

Frequently Asked Inquiries

How Frequently Should I Schedule Upkeep for My Stretch Wrapper?

Upkeep for a stretch wrapper should be set up on a regular basis, commonly every three to 6 months, depending upon usage - stretch wrapper repair. This guarantees peak performance, reduces downtime, and lengthens the equipment's life-span, eventually enhancing overall functional efficiency

Can I Do Basic Repairs on My Stretch Wrapper Myself?

Fundamental repairs on a stretch wrapper may be feasible for individuals with mechanical understanding. Nonetheless, caution is suggested; improper fixings can bring about additional damage and safety risks, stressing the importance of expert help when needed.

What Are the Service Warranty Implications of Do It Yourself Repairs?

The warranty implications of DIY repair work can be considerable. Makers typically void guarantees if unapproved fixings are attempted, resulting in have a peek here prospective financial loss and added prices for professional solution, highlighting the value of sticking to service warranty standards.

Just How Do Ecological Elements Influence Stretch Wrapper Efficiency?

Environmental elements such as temperature, dirt, and humidity can substantially affect stretch wrapper efficiency. Extreme problems might affect product stability, equipment effectiveness, and general productivity, possibly resulting in raised wear and minimized functional lifespan if not appropriately managed.

What Spare Components Should I Stock for My Stretch Wrapper?

To assure peak efficiency, it is recommended to keep essential extra parts for a stretch wrapper, consisting of rollers, belts, film stress springs, sensors, and control panel, facilitating timely fixings and reducing downtime in procedures. Prompt maintenance and repair work of stretch wrappers are critical for service performance. When film tension is inconsistent, it usually symbolizes that a stretch wrapper needs repair. Constant film breakage is a clear indicator that a stretch wrapper may need fixing, additional exacerbating concerns associated to irregular movie tension. Overlooking repair services on stretch wrappers can lead to considerable financial repercussions for companies, as unaddressed problems commonly escalate right into extra severe troubles. Organizations should focus on services that specialize in stretch wrapper repair work, as these service technicians have the required know-how and experience to diagnose and solve concerns effectively.It is advisable to evaluate potential repair work solutions based on their track record, client evaluations, and action times.